Building that timber deck does not just increase the value of your property and give you a cool place to enjoy the outdoors; it’s also an opportunity to do the planet some good.

So how, exactly, does building your deck, pergola, patio, carport and other outdoor living extensions help the planet? Let us count the ways…

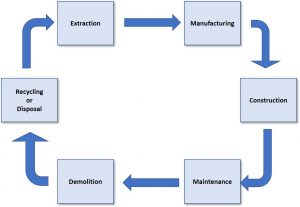

The Life Cycle of Building Materials

Let’s begin by taking a look at the big picture. All building materials, including timber, follow a path that starts when the material is first harvested and continues on until the material is produced and ends when it is finally recycled or disposed. By analysing this pathway using a method called Life Cycle Analysis (LCA), we can assess the impact of the material on the environment at every stage of its life cycle.

Here’s a simplified look at this process.

Of course there are more details involved within the life cycle of building materials and each material may follow a slightly different path because it may have requirements that are unique. But in general this diagram shows the main factors that let us compare timber with other building materials objectively in terms of their particular effect on the environment and its sustainability.

The Environmental Impact of Resource Extraction

A building material’s impact on the environment starts at the point where the raw material for it is harvested. A huge concern during this stage is what is called “unused extraction,” resources that are necessarily extracted during the course of harvesting the raw materials but which are not used. Harvesting trees for timber, for example, leaves loads of residue such as foliage, broken branches and other plants flattened by the falling trees. These are normally left behind as waste even if they can still be used (as fuel, for example). Typically up to a third of the total amount of materials extracted consist of unused resources.

But as wasteful as this may seem, it’s worse for steel and concrete, also popular building materials. The raw material for both steel and concrete are found beneath the surface and need to be mined. This involves moving significant volumes of material — mainly earth material but also including any vegetation and groundwater.

Such waste is a cause for concern because this adversely affects the environment in many ways.

- More vegetation get uprooted as the scale of the mining operation increases.

- Groundwater needs to be pumped out of mines; as the mine grows the volume of groundwater that is pumped out increases. This can upset the ecological balance and cause groundwater shortages for nearby farms.

- As the mine grows, the amount of extracted unused material also grows. When the mining operations cease, you’re left with a huge hole that is expensive or even impossible to rehabilitate.

- Toxic chemicals used in extracting resources can leach out of the mine and pollute nearby sources of clean water.

- Mining operations can lead to soil erosion that affects nearby farms.

The advantage of timber production is that its raw materials — trees — are located above ground and therefore do not require as much effort and energy to harvest, at least not as much as it requires to extract minerals from within the earth. And when trees have been felled and collected, the forest can be rehabilitated by planting new trees and the waste is organic so breaks down as all natural materials do.

Effects of Manufacturing Materials on the Environment

Manufacturing is the next major milestone in the life cycle of building materials. This is when raw materials are processed into the form used in construction. As with extraction, manufacturing also requires inputs and produces outputs that could significantly impact the environment.

Steel production requires extremely high temperatures to process iron ore and to purify it into the final product. Depending on the raw materials used and the intended finished products, the process often involves many stages. Iron ore is sintered before being put through a blast furnace. Steel is then extracted, cast into ingots and continuously refined before it can be fabricated into sheets, bars, pipes, rods and other steel products. Recycled scrap steel is put through a furnace after which the extracted steel is cast and refined in much the same way as steel from raw iron ore.

The by-products of the steel production process include dusts, slag, sludge, chemicals and various solid wastes. Much of these by-products are now recycled back into the manufacturing process but it is still a challenge. One of the problems, for example, is that these by-products tend to mix with each other and processes for sorting them out tends to be expensive. Overall, manufacturing steel is a high energy process generating high volumes of waste that adversely affects the environment.

Concrete production requires grinding and milling the raw materials — limestone, shale, silica and iron oxide — into fine powder. These ingredients are then mixed and heated at extremely high temperatures to fuse them together and drive out any remaining carbon dioxide (which goes back out to the atmosphere, mind you), after which the resulting “clinker” is then ground once more into the cement powder we know and purchase from the stores. As you can imagine, the process likewise requires loads of energy to provide the extreme heating and the mechanical grinding of the raw materials. And you can surely also imagine that these processes produce emissions and waste by-products that don’t do the planet much good. There are a few initiatives from cement producers to curb the negative environmental impact of production. Among the most promising is the development of CO2-absorbing cement.

Speaking at Transform Conference 2019 where he was named Future Green Leader of the Year, Adam Jones stated that “around 8% of the whole world’s greenhouse gas emissions come from the production of cement. Steel production is responsible for about 2-3% of the world’s greenhouse gas emissions.”

Timber is not without its concerns. Sawmills that cut and trim logs into timber require energy to run and produce almost as much by-products as timber itself. That’s the bad news. The good news is, much of the by-products of timber production can be put to good use. Depending on the quality, trimmings from the sawmill can be recycled and used to manufacture products such as panelboards, animal bedding and crop mulches. Lesser grade by-products can be used to produce engineered wood, panel boards and fibre boards. And the remaining can be used as biomass for fuel.

Considering the manufacturing processes of timber, steel and concrete we can easily see that timber production has the smallest carbon footprint among these. Steel and concrete factories require more heavy industrial machinery that are mainly powered by fossil fuels. Many timber sawmills, on the other hand, have been outfitted in large part to make use of biomass generated during timber production.

Construction and Maintenance

Not much goes on for these materials at this point but to be assembled into their respective outdoor structures. Each material follows its own specific assembly procedures and each one has its own prescribed methods for maintenance. Once you’ve built the structure the main interaction with Mother Nature is being in its midst, providing the interface from where you can enjoy it.

A well constructed deck or pergola will give you years and years of enjoyment. Even timber, easily mistaken as the most fragile of these materials, when properly treated and regularly maintained can last up to 50 years, maybe even more. Steel and concrete of course require a small amount of maintenance and will last for a very long time indeed.

Demolition

All things eventually run their course and the time will come — ideally long after you’ve spent endless hours of fun and enjoyment and are ready to move on — when the outdoor extension you have built will need to be torn down and demolished. Perhaps the old structure has seen better days and the material is beyond repair. Or perhaps the new owners want to use the area for something else. Whatever the reason and whatever material you opted for — timber, concrete or steel — that deck or pergola will eventually be torn down. How this affects the environment depends on the material used to build the structure, and how this material is eventually disposed of.

Recycling, Reuse and Disposal

We finally come to the point where the life cycle of building materials comes full circle. There are two options; you can either recycle and reuse the old building material or you can dispose of it altogether. This works with steel, which can be rehabilitated and repurposed or which can be smelted to form brand new metal. Do note that smelting metal calls for re-application of heat and energy and may generate a new set of waste and by-products.

Timber, too, can be reused if the original material is in usable condition or if it requires only minor repair. Recycled timber may also be repurposed; for example timber railway sleepers could be used as fencing and decking boards, and hardwoods previously used as trusses can be repurposed as furniture. Timber can further be reduced and incorporated into fibre boards, engineered wood or composite decking boards.

The options for concrete are not as robust, however. Concrete is not recyclable or reusable, at least not just yet. It will probably end up as landfill somewhere.

The ability to be recycled and reused extends the life of the processed material and certainly takes a load off the earth by easing the pressure somewhat on sources of raw materials. They also limit the amount of unused material and waste products generated.

But when recycling and reuse are no longer possible the only option will be to dispose of the material. In this area timber is most biodegradable and thus most environment-friendly among these building materials. Steel may also be broken down and assimilated back into the environment but the process takes a much longer time than it would for timber. As mentioned earlier, concrete is the least reusable and probably takes the longest to degrade.

The Big Picture

When all these factors within the life cycle of steel, concrete and timber are considered it becomes plain to see the advantages of timber over the other materials. Its ability to store carbon coupled with an overall lower carbon footprint across the entire life cycle, its versatile and robust recyclability and its low impact disposal all contribute to timber being the most environmentally-friendly.

Of course the choice of material for your deck or pergola is a subjective one and depends on your personal preference. But if we are to factor in the effects of the materials we use on our environment, then we need to understand how choosing that material impacts our planet. As the life cycle analysis of building materials helps us see, if we build our decks, pergolas, patios, carports and other outdoor living extensions using timber we will be doing the earth a lot of good.